Standard Operational Sheets

Kummerk provides support in the development of new Procedures and Controls seeking certification based on ISO 9000 standards.

Do we need a change of layout to be more productive; Do we need an extra position to help us in "X" area/process of the Company, Do we need it part time, full time, definite or indefinite term? Management and Senior Management require these answers to decide on the direction the company will take (cost-reduction-management of the company). The Times and Motion Study is a good start.

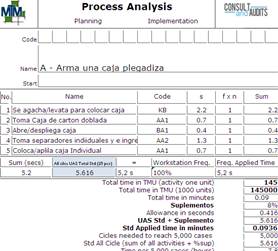

ConsultandAudits offers in Mexico, United States and Canada, the professional Work-Study for resources, operations and processes. The Time and Motion study is a thorough analysis of Times, Movements, operations, environmental factors and work-supplements with the objective to improve productivity and efficiency; The time and motion study can also be called times and movements study in a PMTS environment study.

Time and Motions not only eliminates waste but also helps to determine if the resource is being under-utilized , or unbalanced; the Time and Motions Work Study also determines whether the resources are inefficient or unproductive.

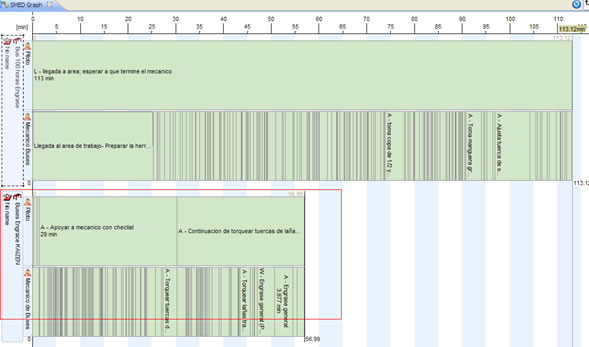

The objective is Balancing operations to allocate production time on such machines, workstations and / or people so that it is necessary for a required output as little time as possible. As we all know, each production or maintenance process consists of several internal and external activities; line balancing, workstation balance, maintenance services balancing, etc. is leveling these internal and external workload across all processes and services among a group of workstations or work-cells or value stream to remove inefficiencies, bottlenecks and excess capacity.

Our Balance Study is conducted in a continuous improvement team-work focus. Our Time and Motion professionals will classify the resource work in 4 areas: 1) Value added, 2) Wait or Loss, 3) Action with opportunity of improvement and 4) Non-productive; this allows our team to focus in the non-value added activities in order to reduce the process cycle time increasing availability, decreasing utilization and reducing costs; this enables the company to be more productive; i.e. produce more with less and reducing production or maintenance costs.

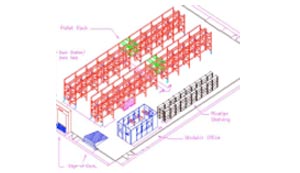

State-of-the-art Balance & Time and Motion software available for consulting or sale

To audit your current production, processes and resources balance with Time and Motion analysis we recommend utilizing the professional services of Consult and Audits

Our Predetermined Motion Time Systems:

Our Predetermined Motion Time Systems:

For more information please contact us at info@consultandaudits.com and ask us about our special offers. Kummerk is a consulting firm which delivers professional services in the US, Canada, Mexico and across Latin-America.

Meet our training courses, workshops and seminars, you can register immediately.

The conditions of the company can be drastically improved

by knowing your products and processes, hidden pitfalls, motivating and implementing improvements in the processes.

Kummerk provides support in the development of new Procedures and Controls seeking certification based on ISO 9000 standards.

Work Study and Time and Motion helps to determine the target standard time of any man-machine activity activity vs the actual cicle time. It also serves to detect and eliminate Non-Value Added activities in any operation, shortening the cycle time in order to comply with the tackt time of the client's demand. For more information about this service please click on “Time and Motion audit”

An MTM UAS Study and motion study, provides a solid foundation for planning and optimizing processes by strengthening cost reduction programs, Lead-Time-reduction and batch-size-reduction. For more information about these services click on “MTM UAS and process Improvement” or also “Six Sigma Consultation"

Time and motion, MTM UAS and Six Sigma. For more information click on “MTM UAS - Six Sigma”

"Kummerk Videos"

Kummerk Logo

Kummerk Flag

Promena e-RFQ e-Auction Sotware

AviX Lean Engineering Software